1. Khetha i-castor yezimboni namasondo

Inhloso yokusebenzisa i-castor namasondo ezimboni ukunciphisa ukuqina kwabasebenzi nokuthuthukisa ukusebenza kahle komsebenzi. Khetha i-castor namasondo ezimboni afanele ngokwendlela yokusebenzisa, izimo kanye nezidingo (ubulula, ukonga abasebenzi, ukuqina). Sicela ucabangele amaphuzu alandelayo: A. Isisindo esithwala umthwalo: (1) Ukubalwa kwesisindo esithwala umthwalo: T=(E+Z)/M×N:

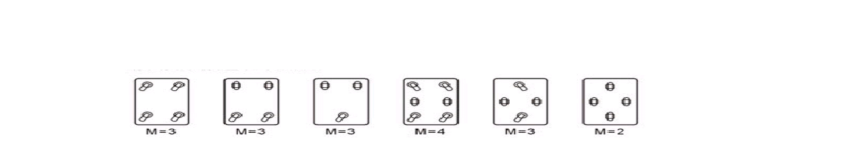

T=isisindo esithwalwa yi-caster ngayinye u-E=isisindo semoto yokuthutha u-Z=isisindo sesiteji esiphathwayo M=inani elisebenzayo lesondo elithwala umthwalo

(izici zokusatshalaliswa okungalingani kwesikhundla nesisindo kufanele zicatshangelwe) (2) Inani elisebenzayo lesondo elithwala imithwalo (M) linjengoba liboniswe esithombeni esingezansi:

E=isisindo semoto yokuthutha

Z=isisindo sesiteji esiphathwayo M=inani elisebenzayo lesondo elithwala imithwalo (izici zokusatshalaliswa okungalingani kwesikhundla nesisindo kufanele zicatshangelwe) (2) Inani elisebenzayo lesondo elithwala imithwalo (M) linjengoba liboniswe esithombeni esingezansi:

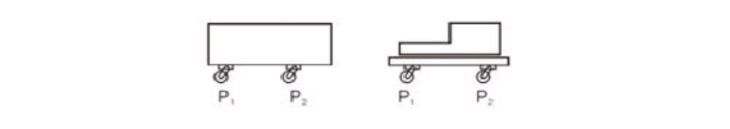

(3)Uma ukhetha umthamo wokuthwala umthwalo, ubale ngokuya ngomthamo wokuthwala umthwalo we-caster endaweni yokusekela ephezulu kakhulu. Amaphuzu okusekela i-caster aboniswe esithombeni esingezansi, kanti i-P2 iyindawo yokusekela esindayo kakhulu. B. Ukuguquguquka

(4)(1) i-castor yezimboni namasondo kufanele kube nezimo, kube lula futhi kuhlale isikhathi eside. Izingxenye ezijikelezayo (ukujikeleza kwe-caster, ukugingqika kwamasondo) kufanele zenziwe ngezinto ezine-coefficient ephansi yokungqubuzana noma izesekeli ezihlanganiswe ngemva kokucutshungulwa okukhethekile (njenge-ball bearings noma ukwelashwa kokucima).

(5)(2) Uma i-tripod inkulu ngendlela engavamile, iguquguquka kakhudlwana, kodwa isisindo esithwala umthwalo siyancishiswa ngokufanayo.

(6)(3) Uma ububanzi besondo bukhulu, kulapho kuthatha umzamo omncane ukulisunduza, futhi kulapho lingavikela khona umhlabathi kangcono. Amasondo amakhulu ajikeleza kancane kunamancane, awavamile ukushisa nokuwohloka, futhi ahlala isikhathi eside. Khetha amasondo anobubanzi obukhulu ngangokunokwenzeka ngaphansi kwezimo ezivunyelwe ukuphakama kokufakwa.

(7)C. Isivinini sokuhamba: Izidingo zesivinini se-Caster: Ngaphansi kokushisa okuvamile, endaweni eyisicaba, kungabi ngaphezu kuka-4KM/H, futhi kube nokuphumula okuthile.

(8)D. Indawo yokusebenzisa: Lapho ukhetha, izinto ezisetshenziswa phansi, izithiyo, izinsalela noma izindawo ezikhethekile (ezifana nokufakwa kwensimbi, amazinga okushisa aphezulu naphansi, i-asidi kanye ne-alkali, imikhuba kawoyela namakhemikhali, kanye nezindawo ezidinga ugesi ophikisana ne-static) kufanele kucatshangelwe. I-castor yezimboni namasondo enziwe ngezinto ezikhethekile kufanele kukhethwe ukuze kusetshenziswe ezindaweni ezikhethekile.

(9)E. Izinyathelo zokuvikela ukufakwa: Ingaphezulu eliyisicaba: Indawo yokufaka kumele ibe yisicaba, iqine futhi iqonde, futhi ingaxegi. Ukuma: Amasondo amabili kumele abe sendaweni efanayo futhi afane. Intambo: Ama-spring washer kumele afakwe ukuze kuvinjelwe ukuxegiswa.

(10)F. Izici zokusebenza kwezinto zamasondo: Siyakwamukela ukuvakashela inkampani yethu noma ucele ulwazi lwekhathalogi.

Isingeniso ekuhlolweni kokusebenza kwe-castor yezimboni kanye namasondo

Umkhiqizo we-caster ofanelekayo kumele uhlolwe ikhwalithi nokusebenza okuqinile ngaphambi kokushiya ifektri. Okulandelayo yisingeniso sezinhlobo ezinhlanu zokuhlolwa ezisetshenziswa amabhizinisi njengamanje:

1. Ukuhlolwa kokusebenza kokumelana Lapho uhlola lokhu kusebenza, i-caster kufanele igcinwe yomile futhi ihlanzekile. Beka i-caster epuletini lensimbi elivikelwe phansi, gcina unqenqema lwesondo luxhumene nepuleti lensimbi, bese ulayisha u-5% kuya ku-10% womthwalo wayo ojwayelekile ku-caster. Sebenzisa i-insulation resistance tester ukukala inani lokumelana phakathi kwe-caster nepuleti lensimbi.

2. Ukuhlolwa komthelela Faka i-caster iqonde phezulu endaweni yokuhlola ephansi, ukuze i-5kg emini iwele ngokukhululeka isuka ekuphakameni okungu-200mm, okuvumela ukuphambuka okungu-3mm ukuthi kuthinte unqenqema lwesondo le-caster. Uma kunamasondo amabili, womabili amasondo kufanele ashaye ngesikhathi esisodwa.

3. Ukuhlolwa komthwalo oqinile Inqubo yokuhlola umthwalo oqinile we-castor namasondo ezimbonini iwukulungisa i-castor namasondo ezimbonini epulatifomu yokuhlola yensimbi evundlile nebushelelezi ngezikulufo, ukusebenzisa amandla angu-800N phakathi nendawo yamandla adonsela phansi e-castor namasondo ezimbonini amahora angu-24, ukususa amandla amahora angu-24 bese uhlola isimo se-castor namasondo ezimbonini. Ngemuva kokuhlolwa, ukuguqulwa kwe-castor namasondo ezimbonini okulinganisiwe akudluli u-3% wobubanzi besondo, futhi ukugoqa, ukujikeleza okuzungeze i-axis noma umsebenzi wokubhuleka we-castor namasondo ezimbonini ngemuva kokuqedwa kokuhlolwa kuyafaneleka.

4. Ukuhlolwa kokugqoka okuphindaphindayo Ukuhlolwa kokugqoka okuphindaphindayo kwe-castor namasondo ezimbonini kulingisa izimo zangempela zokugingqika kwe-castor namasondo ezimbonini ekusetshenzisweni kwansuku zonke. Kuhlukaniswe izinhlobo ezimbili: ukuhlolwa kwezithiyo kanye nokuhlolwa okungenazithiyo. I-castor namasondo ezimbonini afakwe kahle futhi abekwe epulatifomu yokuhlola. I-caster ngayinye yokuhlola ilayishwe i-300N, futhi imvamisa yokuhlola ingu-(6-8) izikhathi/min. Umjikelezo owodwa wokuhlola uhlanganisa ukunyakaza emuva naphambili kwe-1M phambili kanye ne-1M emuva. Ngesikhathi sokuhlolwa, akukho caster noma ezinye izingxenye ezivunyelwe ukususwa. Ngemuva kokuhlolwa, i-caster ngayinye kufanele ikwazi ukuhamba umsebenzi wayo ojwayelekile. Ngemuva kokuhlolwa, imisebenzi yokugingqika, yokujika noma yokubhuleka ye-caster akufanele yonakale.

5. Ukuhlolwa kokumelana nokugoqa kanye nokumelana nokujikeleza

Ekuhlolweni kokumelana nokugingqika, indinganiso ukufaka i-castor yezimboni ezintathu namasondo esisekelweni esingaguquki esinezingalo ezintathu. Ngokusho kwamazinga ahlukene okuhlola, umthwalo wokuhlola ongu-300/600/900N ufakwa esisekelweni, bese kufakwa i-traction evundlile ukuze i-caster epulatifomu yokuhlola ihambe ngesivinini esingu-50mm/S sama-10S. Njengoba amandla okungqubuzana emakhulu futhi kukhona isivinini ekuqaleni kokugingqika kwe-caster, i-traction evundlile ilinganiswa ngemuva kwama-5S okuhlolwa. Usayizi awudluli u-15% womthwalo wokuhlola ozodlula.

Ukuhlolwa kokumelana nokujikeleza ukufaka i-castor eyodwa noma ngaphezulu yezimboni namasondo kumhloli wokunyakaza oqondile noma ojikelezayo ukuze isiqondiso sawo sibe ngu-90° ukuya esiqondisweni sokushayela. Ngokwezinga lokuhlola elihlukene, umthwalo wokuhlola ongu-100/200/300N ufakwa ku-caster ngayinye. Faka amandla okudonsa avundlile ukuze wenze i-caster epulatifomu yokuhlola ihambe ngesivinini esingu-50mm/S bese ujikeleza ngaphakathi kwama-2S. Qopha amandla okudonsa aphezulu kakhulu enza i-caster ijikeleze. Uma ingadluli ku-20% womthwalo wokuhlola, iyafaneleka.

Qaphela: Imikhiqizo ephumelele izivivinyo ezingenhla kuphela futhi efanelekile engakhonjwa njengemikhiqizo ye-caster efanelekile, engadlala indima enkulu emikhakheni ehlukene yesicelo. Ngakho-ke, umenzi ngamunye kufanele anikeze ukubaluleka okukhulu kusixhumanisi sokuhlola ngemuva kokukhiqiza.

Isikhathi sokuthunyelwe: Jan-13-2025